Waste is wealth

Pneumatic transport of bread slices

The use of pneumatic conveying systems to replace traditional methods will have a major impact on production. One might think of improvements in terms of speed, precision and efficiency. Certainly these are aspects that will have considerable benefits, but sometimes there are also advantages that are not immediately perceptible.

Here we describe the design and implementation of a system that we installed in a food company. In particular for the pneumatic transport of bred slices. Apply helped the company’s balance sheet to benefit immediately, which is always a good thing when working in areas where profit margins are more and more reduced.

Production needs

The company was organised with several production lines of considerable length, equipped with conveyor belts. Here bakery products or semi-finished food products such as bread slices, biscuits, toast slices had to be placed, treated and processed. In order for the finished product to have the required characteristics, it was essential that the slices on the conveyor belt remained in their position during the journey, without sliding or rotating. At the same time, since the food products are friable, crumbs, bread residues and dust had to be removed immediately. In other words, the question for our technicians was: how can I keep the processing chain clean and keep the individual pieces in place during transport?

Design and testing of pneumatic transport

Working with the machines designers, the technicians and the production manager, we proposed a solution that would meet all the requirements in a single system. The solution came from the idea of creating perforated conveyor belts. Through these holes the air would both suck in the crumbs and keep the slices in the correct position. The conveyor belt was divided into 2 metre long suction blocks. Thanks to a dedicated suction unit to hold the line in vacuum, bread residues would be sucked up and the conveyed slices held in place with a suction effect.

This solution had never been applied before to such a wide range of food products. How would the slice of bread react on the way? And the toast? Would the cleaning be accurate? So we set up a pneumatic test conveyor project, with a side channel blower, to run several sets of tests. This was followed by an analysis phase directly on the production machines. The result was a number of suggestions for further improvements. Amongst others, it emerged that, with slices not perfectly aligned above the holes in the belt, there could be pressure losses on the suction lines. Apply technicians proposed a brilliant modification on the conveyor belt: from simple through holes to slotted holes, with a countersunk hole profile. The hole pattern was modified, keeping the same diameter on the underside of the conveyor belt and increasing it on the side directly in contact with the product. So even if the slices were not positioned to fully cover the holes, there would be no loss of pressure.

Plant dimensioning

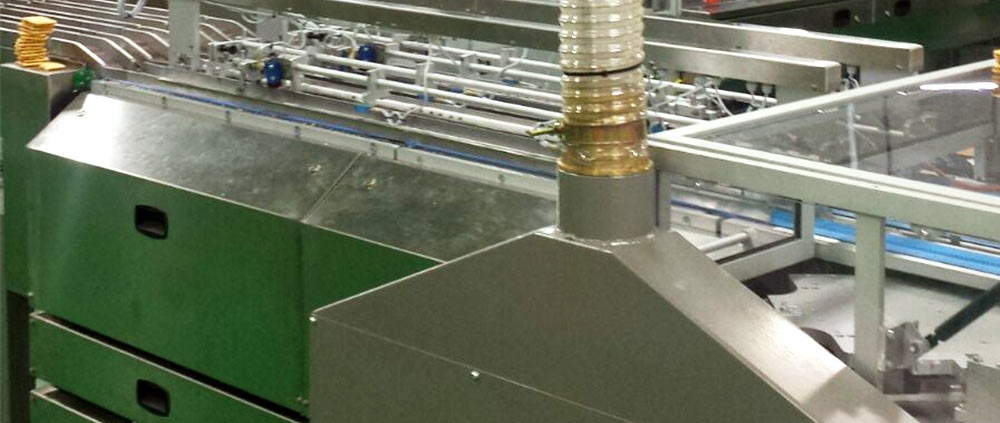

As mentioned, the basic suction block was a 2 metres long conveyor belt. Over this length, 16 suction points were distributed, each equipped with a 30 millimetre diameter channel, all directed towards a stainless steel multi-socket suction distributor with inspection door. From here, a line with 10 centimetres diameter reaches a turbine. With a power of 12.5 kW the turbine can guarantee a 1200 cubic metres flow rate per hour and a vacuum of 250 mbar.

Downstream of the multi-suction air conveyor is a waste collection filter, to prevent crumbs and product dust from entering the turbine. Specifically, this is a filtering sieve that also collects the waste product; the filters are cartridge filters and cleaning is automatic using jets of compressed air.

At the end of all the tests, this pneumatic conveying system proved to be fully satisfactory and reliable with respect to the requests.

No more waste

But the improvements were not over yet. During the tests on the first line, we realised that at standard production rates, due to the diversified treatment of the slices and the nature of the food, the quantity of daily collected crumbs was considerable. Apply engineers proposed turning the whole pneumatic transport system of the bread slices into a non-toxic system, suitable for handling food according to the law. This way, the crumbs could be recovered for other food preparations or for sale to third parties, such as animal feed manufacturers. The waste would become an asset for the company.

The modifications made the entire suction line totally non-toxic, the food material pipes antistatic and the suction distributor in AISI 316L stainless steel. This type of steel differs from AISI 316 stainless steel due to the lower amount of carbon; the letter “L” stands for “low carbon”. This guarantees greater resistance to corrosion and above all greater purity of the product flowing through it. The pneumatic conveying system thus implemented is also FDA certified (Food and Drug Administration, the American agency for food and medicines).

Food production lines for slices of bread with multi-suction distributor.